ball mill parts, ball mill parts Suppliers and ...

Beijing Boqi Electric Power Science & Technology Co., Ltd. Contact Supplier ··· Mining ball mill spare parts. US $1800-$3000 / Ton 1 Ton (Min. Order) 10 YRS . Shanghai Special Metal Co., Ltd. Contact Supplier ··· Ball Mill Spare Parts We can provide professional OEM Service for large cement equipment steel castings. Those cast components, e.g. ball mill spare parts, can be supplied in ...

PARTS OF VERTICAL BALL MILL OF POWER …

Crushing Plant; Spare Parts; … coal power plant ball mill. … raymond coal mill pulverizer in thermal power plant ppt. raymon vertical roller mill for rock … Advantages of Vertical Milling Machine Technology Performance …

ball mill spare parts, ball mill spare parts Suppliers …

450 ball mill spare parts products are offered for sale by suppliers on Alibaba.com A wide variety of ball mill spare parts options are available to you, such as canada, brazil, and malaysia. You can also choose from building material shops, construction works , and machinery repair shops ball mill spare parts, as well as from none, united states, and egypt ball mill spare parts, and whether ...

Cement Plant Ball Mill Spare Parts - Diapharam …

Cement Plant Ball Mill Spare Parts We Are Manufacturing Ball Mill Spare Parts.. Like: Grinding Media Ball, Liner Plate, Conical Plate, Diaphram, Roller, Pinion Etc.

ball mill of power plant - tremitiinbarca.it

spare parts of ball mill of power plant. spare parts of ball mill of power plant Description : pulverizer manufacturers india, coal pulverizer spare ... ball mill in power plant | Mining & World Quarry » feed mill plant pellet mill plant » ball mill thermal power plant » what coal mill, vertical roller mill, raw mill, ball mill etc » beneficiation plant ... ball mills in power plant ...

ball mill manufacturer for power plant

Ball Mill At Coal Power Plant nnguniclub ball mills in coal power plant– Rock Crusher MillRock ball mills in coal power plant XSM is a leading global manufacturer of crushing and milling equipment (ball mills in coal power plant),XSM also supply individual (ball mills in coal power plant) crushers and mills as well as spare parts of them.

Grinding Mills: Ball Mill & Rod Mill Design & Parts

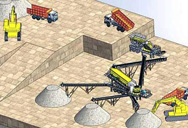

Rod mills in iron ore concentrating plant. Rod mills bridge the gap between crushing and grinding, are often used for preliminary grinding ahead of ball mills. Advantages of wet grinding: Lower power consumption per ton of product. Higher capacity per cubic foot of mill volume. Makes possible the use of wet screening or classification for close product control. Elimination of the dust problem ...

Power Industry – Ball Mills

Thermal Power Plants – Tube Mill Internals - Introduction. IMPROVED WEAR PARTS INCREASES MILL EFFICIENCY IN POWER SECTOR. Efficient fuel processing mills are a critical part of power generation wherever electricity is produced by burning fossil fuels. Following extensive research, Vega Industries, in conjunction with parent company AIA Engineering, has developed a series of …

Ball Mill Design/Power Calculation - LinkedIn

12.12.2016 · Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 ...

Ball Mill Maintenance & Installation Procedure

Parts which are affected by the hand of the mill are easily identified by referring to the parts list. In general they include the feeder, feed trunnion liner, discharge trunnion liner if it is equipped with a spiral, spiral type helical splitter, and in some cases the pan liners when they are of the spiral type. When both right and left hand mills are being assembled, it is imperative that these parts which involve hand be …

BALL MILL DRIVE MOTOR CHOICES - Artec Machine Systems

ball mills, the starting torque restrictions of some of the newer mill drive configurations, and the softness of some utility services. This stone looks at the serviceability and economics of five different mill motor options to meet these restraints. Some approaches are new, some are old standards, and some, like the phoenix, have risen from the ashes to return again. BASIS for COMPARISON ...

Cement ball mill - CHAENG

Motor Power :800-3550 kw ... CHAENG is the top option for cement plant and grinding plant! 2. Provide original spare parts to save customers purchasing time CHAENG has a large casting base, can independently manufacture all spare parts and steel castings of ball mill, to solve customers’ trouble in purchasing parts, and also can provide the spare parts storage service for new and old ...

Ball Mills - an overview | ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig. 2.12). Such a ball mill body is expedient because efficiency is appreciably increased. Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix angle of balls is decreased and ...

Ball Mill: Operating principles, components, Uses ...

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size. The large balls tend to break down the coarse ...

Ball Mill Spares | Ball Mill Parts | HANDY

Ball mill spare parts such as ball mill liners, grinding balls, intermediate diaphragms, etc. are essential wear parts used in the ball grinding mills for fine grinding. Casting parts is a specialized wear parts manufacturer from China. It is proud to manufacture all kinds of wear parts for ball mills. If you need ball mill parts, just send us samples or drawings, based on which we can make ...

Ball Mill In Thermal Power Plant - aachen-friseur.de

Ball Mill In Thermal Power Plant. Types of coal mill used in theraml power plant - global types of coal mill thermal power plant nurseryakg we are engaged in manufacturing and supplying ball mill close circuits ball mill open circuits ball mill girth gear ball mill ball mill for cement . Learn More. High quality products; 100% Factory price; Customized solution; Full after-sales Service ...

Ball Mills, grinders, crushers, ball mill grinding ...

DOVE Ball Mills are made of high – grade cast and carbon steel for extra strength, long and trouble-free operations. Warranty Program All DOVE equipment carry a 2 years (24 months) standard Manufacturer Warranty , which can be extended to 5 years, in addition to lifetime spare parts supply service.

Image of ball mill used in thermal power plant

Image of ball mill used in thermal power plant. COAL MILLS FOR THERMAL STATIONS blogspot Dec 13, 2011The power consumed by the mill per ton of coal ground is only twothirds of the ball mills However if the primary air fan power is also taken into account, in the case of a pressurized mill the power consumption is lower only by about 15%

ball mill machine in power plant - h-h-o.de

schematic grinding ball mill for power plant. Ball millWikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The ball mill is used for grinding materials such as coal pigments and feldspar for pottery. operation similarly it is suitable for open as well as closed circuit grinding and is applicable for materials of all degrees of hardness.