Inlet > Screw Conveyor Parts

The screw conveyor inlet is located at the front of the screw conveyor and allows the material to enter the trough. Inlets are available in a wide range of configurations, thicknesses and material of constructions. The inlets shown in the store are stock and available for immediate shipment. Inlets are sorted primarily by screw conveyor diameter.

Screw Conveyor Inlet Spouts | Component Guide

13 rijen · Inlet spouts are typically located at one end of a screw conveyor on the top of the cover. …

screw conveyor inlets - Scalepaint-Diorama`s

Screw Conveyor Corporation. Screw Conveyor Corporation alog and Engineering Manual . Screw Conveyors are ruggedly built and accurately Inlet and Discharge Openings may be loed wherever needed, dis-charge spouts may be without slides or fitted with either flat or curved slides.

Inlet Works : Screw Conveyor - Wamechsi Group

The Wamechsi Group’s Screenings Screw Conveyor consists of the following key parts: ... The following table and flow chart represents a possibility to select the right unit depending from the inlet flow conditions. Screw Conveyor Length [m] Screw. Conveyor Diameter [mm] Screw Conveyor Capacity [kg/h] Up to 30 . 300.

Screw Conveyor Price | Screw Conveyor …

Forbidden remove screw conveyor cover plate when the working; Screw movement parts should often add lubricating oil. Important conveyors product: Shaftless screw conveyor. Shaftless screw conveyor is mainly composed of drive device, housing, shaftless screw, feed inlet, discharge outlet, etc.

(PDF) Design and Analysis of Screw Conveyor at …

Design and Analysis of Screw Conveyor at Inlet of Ash/Dust Conditioner

Inlet Spouts | Component Manufacturer

Inlet spouts are typically located at one end of a screw conveyor on the top of the cover. Bulk materials enter a screw conveyor through the inlet spout.

Types of Screw Conveyors | Engineering Guide

Horizontal Screw Conveyors. Horizontal screw conveyors are the most widely used type of screw conveyor. Used to convey bulk materials from one part of a process to another, horizontal screw conveyors are available in a wide range of sizes, lengths, configurations and materials of construction.

Screw Conveyor Manufacturer India | Screw …

A screw conveyor is a helical screw-shaped blade mounted on a shaft. Their function is identical to that of screws. It is connected around with a tube or U shaped trough that acts as the conveying surface. Sometimes, this trough is guarded by a cover to ensure the process is cleaner.

Screw Conveyor Example | Engineering Guide

The screw conveyor for the example is control fed at the inlet by another screw conveyor. Screw Conveyor Example – Step 1: Establish Characteristics Of Bulk Material. The first step is to look up stone meal in the Bulk Material Table and write down the following information ...

Shafted Screw Conveyor Manfacturer | Bulk …

Shafted screw conveyors are used in thousands of industrial applications every day for efficiently conveying a variety of bulk materials. A shafted screw conveyor’s main function is to transfer bulk materials from one process to another. Shafted screw conveyors are very cost-effective and require minimal maintenance to operate.

Screw Conveyor vs. Screw Feeder - Blog | Purvis …

31-07-2019 · Screw conveyors: Simply move the material from point A to Point B. The inlet of a screw conveyor will always be control fed by another device such as: another screw conveyor, screw feeder, belt conveyor, bucket elevator, rotary airlock or a volumetric feeder. They can be used up and down inclines. Mixing, cooling, and heating materials can also ...

What is a Screw Conveyor? > Screw Conveyor Parts

A screw conveyor, also called an auger is a mechanical conveying device for powder bulk solids. At the heart of the screw conveyor is the screw. (See here for information on screws) The screw is rotated by the drive and pushes the conveyed material forward 1 pitch with every revolution. The first recorded use of a screw conveyor was by Archimedes around 250 B.C.

Screw conveyor design: The Essential guide to …

A screw conveyor handling such materials are designed to have proper sealing and non-ferrous installations. This will cut the risks involved with handling such material. Screw Conveyor design calculations. Capacity. The capacity of a screw conveyor is given in cubic feet per hour (ft3/hr.) at one revolution per minute.

Coupling Bolts Archives > Screw Conveyor Parts

Screw conveyor coupling bolts are used to connect the screw conveyor shaft to the screw conveyor screw. The coupling bolts are specially designed to transmit the rotational movement of the motor to the screw. The coupling bolts shown in the store are stock and available for immediate shipment. Coupling bolts are sorted primarily by screw conveyor shaft diameter.

FEED AND BIOFUEL CONVEYING EQUIPMENT

Inlet Outlet Outlet D etails: Screw conveyors: Section A-A: Double Screw Series In letai s: 5 e arM otL c i nOp s: * SC - 160 - D - C - 2000 - 1000 - 30 - 1 - 1 - IR - D ... SC-Screw Conveyor 1 2 Screw Size: 160 - 160 Dia Screw 200 - 200 Dia Screw 250 - 250 Dia Screw 315 - 315 Dia Screw 350 - 350 Dia Screw

SCREW CONVEYOR

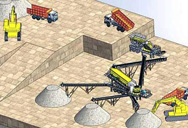

The Screw-Lift does an efficient elevating stone as part of a complete Screw Conveyor system. The Screw-Lift illustrates the compact arrangement possible when space is a concern. Screw Conveyor system and SCC Bucket Elevators being used for speed stone handling in a large facility. Two screw conveyors, running over two rows of tanks are 494 feet ...