Recycled Aggregate - an overview | ScienceDirect …

Recycled masonry aggregate (RMA): aggregate derived from masonry rubble such as ceramics bricks and sand–lime bricks. Mixed recycled aggregate (MRA): aggregate consisting mainly of RCA and RMA. Construction and demolition recycled aggregate (CDRA): aggregate which has not been properly processed from construction and demolition waste, or RA that is unrecognisable due to a lack of …

Reuse of recycled aggregate in the production of …

01-01-2015 · The recycled clay stone aggregate is the weakest and shows the largest fractured surface and is followed in turn by recycled concrete aggregate and normal aggregate. The same authors reported further that the average ratio of splitting tensile to compressive strengths of pervious geopolymer concrete was 14.4%, which was slightly higher than 8–14% for conventional concrete.

(PDF) Recycled aggregates in concrete production ...

01-01-2017 · Recycled concrete aggregate is considered as the most abundant and used secondary aggregate in concrete production, other types of solid waste …

APPLICATION OF RECYCLED AGGREGATE …

07-07-2015 · The production efficiency and influence on the quality of recycled aggregate were established. The basic performance of recycled aggregate concrete, including strength, durability, fire resistance, performance for construction work were examined.

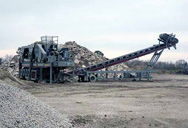

Demolition Techniques and Production of Recycled …

17-06-2018 · The scheme of recycling of construction and demolition waste is elaborated. Various recycling equipment used for production of recycled aggregates are described. A complete recycling technology process for the production of end product i.e. recycled aggregate is described sequentially.

Recycled Aggregate Concrete: Applications, …

15-06-2017 · Recycled aggregate concrete (RAC) is produced in three major steps: Evaluation of Source concrete: The first step in production of RAC is to determine the quality of the source concrete. Properties and records of source concrete like strength, durability and composition are looked into for deciding the proper source concrete.

The Contribution of Recycled and Secondary Materials to ...

and slag from iron and steel production, and are defined as ‘manufactured aggregates’ within the BS EN aggregate product standards. In 2017, a total of 176 million tonnes of primary aggregates were produced by the industry in Great Britain, which, together with an estimated 72 million tonnes from recycled and secondary sources, supplied demand.

Quality protocol: aggregates from inert waste - …

End of waste criteria for the production of aggregates from inert waste. Ref: LIT 8709 PDF, 297KB, 24 pages. This file may not be suitable for users of assistive technology.

recycled aggregate production - …

For production of concrete, 70-75% aggregates are required Out of this 60-67% is of coarse aggregate & 33-40% is of fine aggregate As per recent research by the Fredonia group, it is forecast that the global demand for , Recycled aggregate will be feasible for construction to replace natural aggregat.

Recycled aggregates - MPA - Mineral Products …

Recycled and secondary aggregates are making an increasingly important contribution to the UKs needs. By reducing demand on primary aggregates, they are helping the industry to become more sustainable - in other words, not using up assets today that our children may need tomorrow.

Construction aggregate - Wikipedia

Construction aggregate, or simply aggregate, is a broad category of coarse- to medium-grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates.Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as ...

APPLICATION OF RECYCLED AGGREGATE …

07-07-2015 · PART 1 – EXPERIMENTAL STUDY ON THE QUALITY OF RECYCLED AGGREGATE AND RECYCLED AGGREGATE CONCRETE M Kikuchi Meiji University Japan , T Miura Meiji University Japan , Y Dosho TEPCO Japan , and M Narikawa TEPCO Japan 55 68 A study on the application of recycled aggregate concrete for structural concrete was carried out under the concept of life cycle …

production of recycled aggregate - Hitlers Hollywood

production of recycled aggregate. Often recycled aggregate is combined with virgin aggregate when used in new concrete An example of a mix design using recycled aggregates in a pavement application is shown following table Click here for table Example Mix Design for Recycled Concrete Pavements Sustainability Recycling concrete provides sustainability several different ways

recycled aggregate concrete production

Recycled Aggregate in Concrete - springer. springer, Concrete is the most used man-made material in the world since its invention. The widespread use of this material has led to continuous developments such as ultra-high strength concrete and self-compacting concrete.

(PDF) Prediction of Chloride Ion Penetration of …

Prediction of Chloride Ion Penetration of Recycled Aggregate Concrete Article (PDF Available) in Materials Research 18(2):427-440 · March 2015 with 1,252 Reads How we measure reads