Process Flow-Sheet for Gold and Antimony …

01.10.2000 · Recovery of gold from refractory ores requires a pretreatment to liberate the gold particles from the host mineral. In particular, in the case of stibnite (Sb2S3), the antimony (Sb) forms stable...

Processing of Gold Bearing Antimony Ore: …

05.12.2006 · The preconcentration of antimonite and gold through flotation is technically possible, but one has to take into account gold lost, because some of it is embedded in the quartz. The gold was almost selectively and fully dissolved in the leaching solution when an oxidizing ammoniacal pressure leaching was carried out.

A selective process for extracting antimony from ...

01.05.2017 · To avoid the adverse effects of antimony on the cyanide leaching process used for the recovery of gold from refractory gold ore, a cleaner production process was proposed that would selectively remove antimony as sodium pyroantimonate.

How Antimony is Processed by Flotation

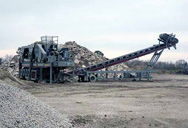

Metallurgical ContentCRUSHING SECTIONGRINDING CIRCUITCONDITIONING AND FLOTATIONCONCENTRATE THICKENING AND FILTERINGSAMPLINGLABORATORY TESTINGMARKET SPECIFICATIONSREAGENTS The problem discussed in this antimony process study is limited to a concentrator capable of beneficiating 150 tons per day of antimony ore. The antimony …

processing gold in antimony ores - De …

Process flow-sheet for gold and antimony recovery from stibnite , Recovery of gold from refractory ores requires a , on the gold recovery process Antimony was .... Antimony ore processing Antimony ore proportion is heavy than matrix , normally gravity separation is more efficient , its efficiency , economic , environment protection and concentrate the ....

Antimony ore processing flow chart and plants

Nature of antimony ore decides the antimony ore processing flow chart and the beneficiation method. The general antimony upgrading covers hand selection, gravity separation, and floatation separation. Flow sheet of energy-saving and high upgrading efficiency has been required. Here is a combination of gravity separation-floatation separation-gravity separation for antimony ore to share with you.

Antimony Ore Processing Methods-Jaw Crusher

Equipment For Processing Gold In Antimony Ores. Antimony ore processing introduction of antimony ore processing the antimony ore beneficiation methodsshould be based on the type of oremineral compositionmineral structure and embedded pot and other physical and stone properties as the basic conditions to select you should also consider a price component content and meet the . …

Hydrometallurgical processes of antimony …

07.09.2016 · Abstract. Data concerning the preparation of antimony and complex ores by pyrometallurgical and hydrometallurgical methods, as well as results on developing a procedure for the hydrometallurgical processing of slime antimony concentrates using …

Establishing thE ProcEss MinEralogy of gold orEs

Establishing thE ProcEss MinEralogy of gold orEs JoE Zhou, brucE Jago and chris Martin –– sgs lakEfiEld rEsEarch liMitEd abstract From the perspective of metallurgical processing, gold ores can be classified into free-milling and refractory ores. Their extractive metallurgy are largely driven by mineralogical factors such as: gold particle size, association with other minerals, coatings ...

Refractory Gold Ore Treatment Methods

Metallurgical ContentGold Leaching & Processing of Arsenic OreMispickel (Arsenopyrite: FeAsS).6Leaching and Recovering Gold from Antimony MineralsStibnite (Antimony Sulphide, Sb2S2)Telluride Gold Ore ProcessingSolubility of TelluridesGold Extraction from Carbonaceous OreList Gold Refractory Process Methods Where gold is associated with arsenic, antimony, tellurium, and …

Processing of Gold Containing Antimony Ores

Processing of Gold Containing Antimony Ores #G-723 Physical Chemistry and Development of Complex, Environmentally Safe Technology Processing of Gold containing Antimony Ores of Georgia

(PDF) Cyanidation of gold ores containing copper, …

The gold processing industry is experiencing change. As free-milling and oxide ores become depleted, more complex polymetallic and refractory ores are being processed, coupled with increasing ...

antimony gold ore refinery - jpchoir.co.za

Antimony Gold Ore Refinery - rolvaplast.be. antimony refinery south africa - zakenclubtzand.nl. antimony trio ide refining south africa - inperfectestaat.nl. antimony processing machine supplier south africa antimony, antimony trio ide refining south africa Antimony trioxide gold refining Implats is South Africa39;s Refining of Gold at the Rand ...

How Is Gold Extracted From Gold Ore? | Sciencing

Several processes can then be used to separate the gold from the ore. The most common techniques in the United States use cyanide in various ways. In one, the ground ore is put into a tank containing a weak cyanide solution and zinc is added. The zinc causes a stone reaction which separates the gold from the ore. The gold is then removed from the solution with a filter press.

Improved gold and silver extraction from a …

01.01.2011 · 1. Introduction. Gold-bearing ores can be classified as either free milling or refractory based on their metallurgical response to cyanide leaching (Adams, 2005).While high gold recoveries (> 90%) from free milling ores can be readily achieved, refractory gold ores are often characterized by the low gold extractions (< 80%) by conventional cyanide leaching (Gupta and Mukherjee, 1990).

US1964781A - Process for separating gold and …

US1964781A - Process for separating gold and antimony contained in antimony sulphide ores - Google Patents Process for separating gold and antimony contained in antimony sulphide ores Download PDF Info Publication number US1964781A. US1964781A US479075A US47907530A US1964781A US 1964781 A US1964781 A US 1964781A US 479075 A US479075 A US 479075A …

Antimony ores : Importers, Buyers, Wholesalers …

5300+ antimony ores Buyers-Importers – Access to antimony ores Wholesalers, Distributors, Purchasing and Trade Managers, Traders and Importers Directory.Get Latest antimony ores buying leads, quotations and buy offers from China Importers, …

Gold extraction - Wikipedia

Gold extraction refers to the processes required to extract gold from its ores.This may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

antimony gold ore extraction in anguilla

The extraction of Antimony from its ore The following photographic documentation of the process of extracting antimony from its ore made by one of my French Gold extraction – Wikipedia the free encyclopedia Gold extraction or recovery from its ores may require a combination of comminution mineral processing hydrometallurgical and . Geology of the Tungsten Antimony and Gold Deposits. …

Antimony Mineral Processing - hotminingepc.com

Antimony Mineral Processing . Process Introduction. Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation.This method has many features, high efficiency, energy saving, and environment protection, which can make the low-grade ore enrichment advance.