reduction size reduction mechanism in hammer …

Hammer mill methods of size reduction - zotvanbier. Hammer mill methods of size reduction. Whether your goal is data destruction commodities reclamation or a combination of the the two the most common methods of size reduction for escrap processing are shredders and hammer mills But which is best for your material and processing goals Our free ...

(PDF) METHODS OF SIZE REDUCTION AND …

09-09-2013 · methods of size reduction and factors affecting size reduction in pharmaceutics Article (PDF Available) in International Research Journal of Pharmacy 4(8):57-64 · …

Size Reduction - an overview | ScienceDirect Topics

Size reduction is one of the most effective methods for increasing the enzymatic accessibility to lignocellulose. However, many of the physical methods for size reduction (milling, grinding, etc.) are not economically feasible because a very high-energy input is required.

Hammer mill working animation HD - YouTube

26-08-2016 · In a hammer mill, swinging hammerheads are attached to a rotor that rotates at high speed inside a hardened casing. It is used in the size reduction of sugar, tapioca, dry vegetables, extracted ...

Hammer Mills: A Reliable Solution for Particle Size …

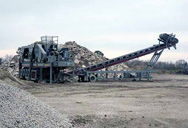

In order to break down oversize product, size reduction equipment is employed, and while there are a variety of size reduction equipment types available, one option, the hammer mill, offers a reliable size reduction tool for many applications.

Particle Size Reduction Methods: Which Is Best?

Particle size reduction is a crucial initial step in the production of countless end products across all manufacturing industries. Think of wheat that needs to be ground in the production of flour, or rocks and rubble that must be crushed in order to make sand, and pharmaceutical ingredients that need to be finely milled for incorporation into drugs.

Hammer Mill For Size Reduction In Kenya

Hammer Mill For Size Reduction In Kenya. FOB Reference Price: Get Latest Price We have Hammer Mill For Size Reduction In Kenya,For size reduction equipment please tell us more about your process by completing our size reduction application data form complete please click the button at the bottom of the page to submit the form

Top 5 product-specific milling technologies used in ...

Impact and attrition size-reduction methods include air classifying mills, pin mills, hammer mills and jet mills. Shear, impact and compression methods are used in media or ball mills. The five types of milling technologies discussed in this article cover more than 90 percent of size-reduction applications in major chemical, food, pharmaceutical, cosmetics and mineral industries.

hammer mill reduction ratio - bbdeicolli.it

Crusher Size Reduction Ratio Calculation Method. 2015-7-14 Generally, every crusher machine is not the same, here are several common crusher size reduction ratio: The impact crusher size reduction ratio is 20 to 1. The vertical shaft impact crusher size reduction ratio is 4-8 to 1. The vertical roller mill size reduction ratio is 2-2.5 to 1.

PARTICLE SIZE REDUCTION TECHNIQUES

25-03-2016 · Size reduction may be achieved by two methods: 1] Precipitation 2] Mechanical process 1] Precipitation method: Substance is dissolve in appropriate solvent. 2] Mechanical process: Mechanical force is introduce by using different equipments like ball mill, colloid mill etc. 3

unit operation size reduction hammer mills

operation size reduction hammer mills progetto-lithos. list of manufacturer of feldspar size reduction by ball,The analysis of size reduction in tumbling ball mills using the,milling machineries for pharmaceutical unit operations,Milling & Size Reduction,hammer mill .

Hammer Mill: components, operating principles, …

11-01-2016 · Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

Optimizing hammer mill performance through screen ...

Hammer mills are recognized as technology capable of finely grinding the greatest variety of materials [3,13] and are noted for achieving high size-reduction ratios and yielding cubic-shaped particles [14,15]. Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil - ity [16].

Complimentary Size Reduction Testing | Schutte …

• Determines what method of feeding and discharging of the mill is most practical. While this testing is at no charge to you, we do require that our customers provide us with the specific product they are seeking to process, be responsible for the cost of shipping the material to us, and, if there is any remaining material following the test, for its return.

Size Reduction - Visual Encyclopedia of stone …

Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher , also called the hammer mill, is an example of an impact crusher. In hammer crushers, hammers swing freely on a disc mounted on the main shaft within the device .

Hammer mills: hammermills - Feed Mill Machinery …

There are a many ways to achieve this particle size reduction, here we are looking at using hammer-mills, for information on roller mills, see the related links at the bottom of this page. Both hammering and rolling can achieve the desired result of achieving adequately ground ingredients, but other factors also need to be looked at before choosing the suitable method to grind.

hammer mill methods of size reduction - team …

Size reduction techniques. The four basic techniques used in size reduction of dry powders are impact, shear, attrition and compression forces. In some cases, a combination of these may be found in a single mill type. Impact and attrition size-reduction methods include air classifying mills, pin mills, hammer mills and jet mills.