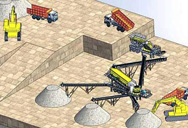

coal storgage coal handling and coal mill

ball mill in coal handling plant - Simone Pachur. ball mill in coal handling plant. In this post you learn about what is coal handling plant it’s layout requirement for coal handling plant method of coal storage and fuelburning ash handling and it’s treatment Coal Handling Layout A simple arrangement of race and ball mill is shown in the figure It consists of upper and lower races and ...

Coal Storgagecoal Handling And Coal Mill

Coal Storgagecoal Handling And Coal Mill. The difference in strengths given above is basically due to difference in all standards the 3 days strength is nearly 112 to 2 times of o.p.c. the disadvantages of this cement beside its higher cost are its high heat of hydration, which renders it unsuitable for mass ...

COAL HANDLING SAFETY - AMETEK Land

COAL HANDLING SAFETY Risks of unwanted combustion – potentially causing injury, damage and downtime – occur everywhere that coal is handled, processed or stored. Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey from the mine until the point at which it is ignited in the boiler.

coal handling coal mill safety - autourdurocher.fr

mill in coal handling plantaubergeducerf . COAL HANDLING SAFETY . Even in routine mill shutdowns there is a danger that any residual coal left within the mill will oxidise and may explode as the mill is restarted. The Millwatch system is installed near the classifier and can detect the CO emitted from any hot inclusions within the residual coal.

Coal handling plant in a thermal power generating …

04-03-2012 · The crushed coal is then transported to the store yard. Coal is transported to bowl mills by coal feeders. 3. Bowl Mill. The coal is pulverized in the bowl mill, where it is grounded to a powder form. The mill consists of a round metallic table on which coal particles fall. …

Coal Handling System - SlideShare

21-08-2016 · INPLANT COAL HANDLING The In-Plant coal handling system deals with feeding of coal from live storage to the furnace. It includes various equipments for transfer of coal like belt conveyor, screw conveyor etc. & the equipment needed to weigh the quantity of coal for feed. In case of pulverized coal firing system, it requires large no. of equipment’s like chutes, pulverized mills, feeders ...

Fine Coal Storage Silos | Sanghavi Group

Fine Coal Handling System. We Design, Manufacture and Supply the entire coal mill circuit from the Mill Feeding to the burner. The Fine Coal generated in mill System is to be handled for Storage, Extraction and Transfer to the required utility area for usage. This needs special care as environment and safety plays a major role.

Eggborough Power Station – Coal Handling – …

A “merry-go-round” train delivering coal, 1970. The 345 acre coal storage yard at Eggborough power station had a capacity of 1.75 million tons of coal, which is equivalent to 15 weeks supply. Fuel was originally drawn from the Yorkshire coalfields and consisted of small coals unsuitable for domestic use.

Storage of Coal: Problems and Precautions

The coal stacks formed in open areas can be generally in cone, prism, cut cone/prism, etc. shaped. Geometric shapes frequently used in coal stacking are shown in Figure 2. Figure 2: Examples about Stacking Geometry of Coal (Mine Storage, 1959) 3. Problems Faced in Coal Stacks Besides various advantages, stacking presents also some disadvantages.

Coal Mill - an overview | ScienceDirect Topics

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

Coal and ash handling systems - LinkedIn SlideShare

Coal handling storage of coal • Under water storage: • The possibility of slow oxidation and spontaneous combustion can be completely eliminated by storing the coal under water. 7. Live storage or active storage • Coal from a live coal storage pile is usually supplied to combustion equipment without the use of mobile equipment.

Coal Ash Handling & Storage: Shifting Direction | …

01-02-2013 · Four years after more than one billion gallons of coal ash slurry spilled from a storage pond at the Kingston Power Plant in eastern Tennessee, environmental groups are still waiting for the U.S ...

Comparing coal handling system costs | Power …

01-03-1996 · Fuel handling. Comparing coal handling system costs. By John M. Lehto, Northern States Power Co., Sherburne County Generating Plant. Good maintenance practices and proactive planning are …

Fotemine machinery is the large manufacturing …

Conveyor Belt Tracking Problems Coal Surface Mining; How Much Air Flow For Alstom Rs 663 Coal Mills; Project Report For Coal Crushing And Coal Screening In Pdf Format; Mobile Coal Jaw Crusher Manufacturer; Portable Coal Crusher Provider; Abb Ex Coal Mill Melbourne; Coal Crusher Grinding Mill; Coal Supply Riding; Grinding Roller Coal Mill

Coal-fired power station - Wikipedia

A coal-fired power station or coal power plant is a thermal power station which burns coal to generate electricity.Coal-fired power stations generate over a third of the worlds electricity but cause hundreds of thousands of early deaths each year, mainly from air pollution.. A coal-fired power station is a type of fossil fuel power station.The coal is usually pulverized and then burned in a ...

Coal grinding systems - Safety considerations - …

10-09-2015 · Coal mill hot air inlet temperatures should never be more than 600 ° F and the outlet temperature should not exceed 200°F on Raymond coal mills. If the flow of raw coal to the coal mill is interrupted for any reason (for example: plugging, failure of the coal feeder, etc.), the outlet temperature of the coal mill can quickly climb to dangerous levels.

coal storgage coal handling and coal mill – …

coal storage and handling ppt – Grinding Mill China. Coal Handling Ppt Presentation – PowerPoint Presentations … Coal Handling Ppt Presentation … Crushed coal storage capacity 21 days… » Learn More. coal handling storage chinese guidelines or - BINQ Mining. Coal Handling & Energy Bulk Solids Storage for NFPA.

Coal Handling - Global Training Solutions - Global ...

Coal Handling. To help companies improve the knowledge and skills of workers and meet the demands of today’s busy training manager, Global Training Solutions Inc. offers a practical solution with 20 Web delivered coal yard handling training units.

Safety Precautions in Coal Handling and Firing.docx ...

Coal with high moisture content will need a higher coal mill inlet temperature for drying purposes. Asec Academy Safety Precaution in Coal handling & Firing 3 Accumulation of coal dust during system operation During operation of the coal pulverize and the coal-dust-handling facilities, coal fines can collect at dead areas within the pulverize and at bends in ducting.