Coal Processing - an overview | ScienceDirect Topics

Dilip Kumar, Deepak Kumar, in Sustainable Management of Coal Preparation, 2018. Abstract . Dry coal cleaning has claimed an important place in the current coal processing technology. The most important and reliable plants include rotary breakers, air jigs, FGX separators, air dense-medium fluidised bed separators, radiometric sorters and others. The rotary breaker has a dual role of crushing ...

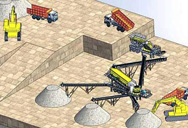

coal preparation and processing facility

1 3 Fleet status The United States currently operates 268 coal preparation plants in 14 states according to the latest annual census of coal processing plants conducted by Coal Age The facilities which are primarily located in West ia 80 Kentucky 56 and Pennsylvania 44 represent a total installed feed capacity of over 200 000 tons per hour

Expert Witness; John Cantwell; Mineral Processing ...

Expert Witness and Technical Audit Service of mineral processing, coal preparation and bulk material handling facilities with regard to engineering design, construction issues, equipment performance, personnel training, startup issues, safety and quality control.

Coal Preparation - an overview | ScienceDirect …

Coal preparation, or beneficiation, is a series of operations that remove mineral matter (i.e., ash) from coal. Preparation relies on different mechanical operations (not discussed in detail here) to perform the separation, such as size reduction, size classification, cleaning, dewatering and drying, waste disposal, and pollution control.

Pennsylvania Mining Complex | CONSOL Energy Inc.

The Pennsylvania Mining Complex, located in Greene and Washington counties, is the largest underground coal mine complex in North America. Consisting of the Bailey, Enlow Fork and Harvey mines, along with the central preparation plant and train loadout facility, it is among the safest and most productive complexes in the world.

Mineral Processing - Coal Preparation - CTC

Advanced Coal Preparation The course is aimed at more senior mineral processing personnel, and provides the student with a wider and more advanced scope regarding Coal Preparation and utilisation in general. It also prepares the student to play a more meaningful role in the management of the ore beneficiation environment.

Ch. 89 UNDERGROUND MINING OF COAL

The term includes a facility associated with the coal preparation activity and the activity by which the land surface has been or is disturbed as a result of or incidental to coal preparation activity of the operator including, but not limited to, the following: (i) Private ways and roads appurtenant to the area, land excavations and loading facilities.

Environmental, Health and Safety Guidelines for Coal ...

Coal preparation activities (e.g., use of dryers), coal gasification , feeding and ash removal) and coal liquefaction processes may generate point-source emissions of dust and heavy oils (tars). Appropriate technology should be selected to minimize 4 Examples include: API Standard 620: Design and Construction of Large, Welded, Low-pressure Storage Tanks (2002); API Standard 650: Welded Steel ...

Certificate III in Resource Processing - RII30415 - …

This qualification reflects the role of employees such as production operators in a metalliferous processing facility or a coal preparation and treatment plant, who perform tasks involving a broad range of skilled applications in a varied work context, using some discretion and judgement in selecting equipment, services or contingency measures.

Subpart Y—Standards of Perform- ance for Coal Preparation ...

ance for Coal Preparation and Processing Plants SOURCE: 74 FR 51977, Oct. 8, 2009, unless otherwise noted. §60.250 Applicability and designation of affected facility. (a) The provisions of this subpart apply to affected facilities in coal prep-aration and processing plants that process more than 181 megagrams (Mg) (200 tons) of coal per day.

The Daniels Company | Design and Build for Coal ...

Design and Construction of Coal Preparation Facilities Design of Material Handling Systems including Batch-weigh Loadouts Design and Erection of Modular Coal Preparation Facilities Development & Translation of well-designed flowsheets into cost-effective & efficient coal prep facility Fabrication of a variety of equipment used to process coal Welcome Welcome to The Daniels Company (a member of ...

Coal Handling & Preparation Plants | Ausenco

Our aim is to deliver superior coal process solutions for our clients - big or small, regardless of the location. Our end to end solutions are proven to lower capital and operating costs, reduce construction time and improve plant efficiencies. We ensure that our coal processing solutions are tailored to your specific needs to help you to achieve your goals. We provide an array of solutions ...

40 CFR Subpart Y - Standards of Performance for …

§ 60.250 Applicability and designation of affected facility. § 60.251 Definitions. § 60.252 Standards for thermal dryers. § 60.253 Standards for pneumatic coal-cleaning equipment. § 60.254 Standards for coal processing and conveying equipment, coal storage systems, …

Coal breaker - Wikipedia

A coal breaker is a coal processing plant which breaks coal into various useful sizes. Coal breakers also remove impurities from the coal (typically slate) and deposit them into a culm dump.The coal breaker is a forerunner of the modern coal preparation plant.. Generally speaking, a coal tipple was typically used at a bituminous coal mine, where removing impurities was important but sorting by ...

flow sheet of a coal processing plant - Popular …

U.S. coal-fired power plants is prepared for market by coal processing facilities. Modern ..... FIGURE 4.3 Simplified flowsheet for a modern coal preparation plant. Read More . Coal Preparation Plants - Mine Engineer . A flow diagram of a 400 ton per hour coal plant that produces both metallurgical coal and steam coal for power generation. Generally speaking, metallurgical... Read More. Coal ...

Proposed Approach for Coal Mining Effluent Regulations

screening, crushing, grinding, washing and other processing of coal that occurs at a coal mining facility (i.e., coal preparation facilities). All of these activities are proposed to be captured by the regulations since they are capable of generating effluent. The definition of a coal mine is proposed to include its operations area. • Effluent: includes liquid discharge from a coal ...

CTC | Colliery Training College

The current courses presented at CTC are aimed at mineral processing but are also applicable to other beneficiation processes. Both the Basic and Advanced courses Unit Standards are accredited by the MQA and are being presented under the auspices of the South African Coal Processing Society. Basic Coal Preparation for Plant Operators. The course is presented over a period of 7 weeks, 2 days ...