liming Ball Mill For Iron Ore Fines Details For Pellet …

Mining Ball Mill For Iron Ore Fines Details For Pellet, Mining ball mill for iron ore fines details for pellet summary vales production and sales in 3q19iron ore fines and pellet sales volume amounted to 851 mt in 3q19 202 higher than 2q19 as a result of the above mentioned production resumption liming Ball Mill For Iron Ore Fines Details For Pellet Plant

ball mill for iron ore fines details for pellet plant

Mill ball mill for iron ore fines details for pellet plant.Ore ball mill pellet plant for sale mill for iron ore fines details for eum coke ball mill gypsum grinding millfind complete details abouta type of ball grinding mill is the key equipment for grinding materials into fine e the falling course of iron balls and ores can produce huge falling. Get Price. SAFETY GUIDELINES FOR IRON & STEEL ...

ball mill for iron ore fines details for pellet plant

CachedIron Ore Pellet Ball MillCachedsmall scale iron ore ball mill pellet plant for sale The Iron ore fines generated during the excavation process Read more ball mill in pellet plants 18 574 USD Chinese Manufacturer of stone Pellet Mills and Complete AKG BiofuelTe. 24/7 Online ball mill pellet plantparkhurstprimarycoza

Ball Mill For Iron Ore Fines Details For Pellet

Ball Mill For Iron Ore Fines Details For Pellet. La meccanicas hammer mills are characterized by heavy duty construction direct coupling of rotor through an elastic coupling bidirectional rotation rotor with dynamic balance screen that can be manually withdrawn from the side of the mill, temperature sensor pt ...

ball mill for iron ore fines details for pellet - Genius

Ball mill for iron ore fines. Tphball mill for iron ore fi neswhitehillstree. tphball mill for iron ore fi nestphball mill for iron ore fi nesinfluence of raw material particle size on quality ofpellets. jul 18, 2013 .iron ore finesof 10 mm size and limestone are ground together in aball millto get sufficient fineness for the balling process. however,.

Iron ore pelletizing systems - liming

Iron Ore Pellets are formed from beneficiated or run of mine iron fines. The iron is usually ground to a very fine level and mixed with limestone or dolomite as a fluxing agent and bentonite or organic binders as a binding agent. If the ore is a Hematite ore, coke or anthracite coal can be added to the mix to work as an internal fuel to help fire the pellets. This mixture is blended together ...

small scale iron ore ball mill pellet plant for sale

Ball Mill For Iron Ore Fines Details For Pellet, pelletizing machine for iron ore grinding mill ,ball mill for sale ball mill is the most , small scale iron ore ball mill pellet plant for saleThe ores are . small scale iron ore ball mill pellet plant for sale - , mill crusher small scale iron pellet plant small scale iron ore ball mill pellet plant for sale stone crusher for sale More details ...

Iron Ore Processing for the Blast Furnace

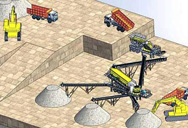

The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2"). Pellets are screened to ...

Understanding Pellets and Pellet Plant Operations …

Understanding Pellets and Pellet Plant Operations. satyendra; March 21, 2015 ; 0 Comments ; disc pelletizer, grate kiln proces, Pelletization, pellets, rotating drum, Travelling grate process, Understanding Pellets and Pellet Plant Operations. Pelletizing is an agglomeration process which converts very fine grained iron ore into balls of a certain diameter range (normally 8mm to 20 mm, also ...

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology & Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron & Steel Business

Brahmani River Pellets Limited

BRPL is in operation in producing iron ore pellets from iron ore concentrates after beneficiating low grade iron ore fines. The low grade fines with Fe less than 56-57% are beneficiated at beneficiation plant through grinding, gravity & magnetic separation process to produce high grade iron ore concentrates with 63-64% Fe. This high grade iron ore concentrates in form of slurry is transported ...

Reducing Grinding Energy and Cost -Magnetite …

With these ores, there is significant cost associated with milling the ore to fine sizes using ball mills in closed circuit with hydrocyclones. Cyclone classification efficiency tends to be poor ...

Iron Ore and Pellets - Vale

Vale is the world’s biggest producer of iron ore and pellets, raw materials essential to the manufacture of steel. Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cutting-edge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and ...

Ball Mill Used In Iron Ore Beneficiation Plants

Roller screens are used in iron ore pellet plants when it is essential to prevent breakage of pellets and efficient separation of fines for recycling back to pelletisers directly for sale or for further grinding to micron sizes by ball mills grinding mill basically rod mills grinding millare used in iron ore beneficiation . come look; China Top Used Hematite Iron Ore Beneficiation Line. China ...

China Iron Ore Pellet Plant, Iron Ore Pellet Plant ...

China Iron Ore Pellet Plant manufacturers - Select 2020 high quality Iron Ore Pellet Plant products in best price from certified Chinese Mining Equipment manufacturers, Mineral Machinery suppliers, wholesalers and factory on Made-in-China.com

Pelletizing - Wikipedia

Iron ore pellets are spheres of typically 6–16 mm (0.24–0.63 in) to be used as raw material for blast furnaces.They typically contain 64–72% Fe and various additional material adjusting the stone composition and the metallurgic properties of the pellets. Typically limestone, dolomite and olivine is added and Bentonite is used as binder.

Ball Mills - Mineral Processing & Metallurgy

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle & OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill & Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll ...

Pellets - Iron Ore Pelletization Plant Manufacturer …

Iron Ore Pelletization is an agglomeration process of the disintegrated Iron Ore fines into Iron ore Pellet which is suitable for the utilization of downstream process of Iron Making. The GPIL Process is the Ore ground to the required fineness through wet grinding process mainly by Ball Mills and the slurry is dewatered by pressure filtration to produce the Iron Ore Concentrate.The Iron Ore ...

(PDF) Improving reducibility of iron ore pellets by ...

06.12.2015 · Pellet plant (4·2 MPta capacity) of JSW Steel Ltd imports iron ore fines from different mines to produce pellets for its Corex and Blast Furnace plants…